|

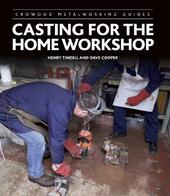

Casting for the Home Workshop

Hardback

Main Details

| Title |

Casting for the Home Workshop

|

| Authors and Contributors |

By (author) Henry Tindell

|

|

By (author) Dave Cooper

|

| Series | Crowood Metalworking Guides |

|---|

| Physical Properties |

| Format:Hardback | | Pages:128 | | Dimensions(mm): Height 260,Width 215 |

|

| Category/Genre | Decorative wood and metalwork |

|---|

| ISBN/Barcode |

9781785003530

|

| Classifications | Dewey:671.2 |

|---|

| Audience | |

|---|

| Illustrations |

Diagrams; Halftones, black and white; Halftones, color; Illustrations, unspecified; Diagrams; Halftones, black and white; Halftones, color; Illustrations, unspecified

|

|

Publishing Details |

| Publisher |

The Crowood Press Ltd

|

| Imprint |

The Crowood Press Ltd

|

| NZ Release Date |

19 February 2018 |

| Publication Country |

United Kingdom

|

Description

The techniques of casting are of crucial importance in our day-to-day lives, being used in the manufacture of diverse products ranging from dental implants and hip replacement joints, through bicycle frames and car engine parts, to the most exquisite items of sculpture and jewellery. Nevertheless, the prospect of casting can seem daunting to the home metalworker. Casting for the Home Workshop aims to demystify the craft and make it accessible to all. Topics covered include the history of casting; tools, materials and equipment; techniques; the home foundry and post-casting operations. AUTHORS: Henry Tindell is a chartered engineer, with a thirty-five year career behind him. He gained a double first in Metallurgy and Mechanical Engineering from the University of Manchester, followed by an M.Sc and Ph.D for work on metal-matrix composites for orthopaedic surgery. Now semi-retired, he works as a consultant and home workshop-based engineer. Dave Cooper undertook an apprenticeship as a moulder coremaker and has worked in both ferrous and non-ferrous foundries, making items ranging from bronze propellers to cast iron lathe beds. He has always been interested in steam and is currently working on making a beam engine, making the pattern moulds and cores himself, before undertaking the casting, machining and assembly. 280 colour and 75 b/w photographs

Author Biography

Henry Tindell is a chartered engineer, with a thirty-five year career behind him. He gained a double first in Metallurgy and Mechanical Engineering from the University of Manchester, followed by an M.Sc and Ph.D for work on metal-matrix composites for orthopaedic surgery. Now semi-retired, he works as a consultant and home workshop-based engineer. Dave Cooper undertook an apprenticeship as a moulder coremaker and has worked in both ferrous and non-ferrous foundries, making items ranging from bronze propellers to cast iron lathe beds. He has always been interested in steam and is currently working on making a beam engine, making the pattern moulds and cores himself, before undertaking the casting, machining and assembly.

|